Resources

-

Dincel Manuals

Download the latest Dincel Constructions Manuals and Installation Manuals to assist with your Dincel installation.

-

BIM Files

Dincel BIM files available to use: Family, Systems and Individual files.

-

Tech Sheets

A wide range of Tech Sheets available detailing product specifications.

-

Renders & Finishes

Information on render and finish options for Dincel Structural Walls.

-

Brochures

Download the latest brochure and info sheets from Dincel Civil Solutions.

-

Compliance

The latest documents and information on Dincel compliance.

-

Tools & Fixing

Information for the recommended tools and fixings to use for Dincel installations.

-

Sustainability

Download the latest Dincel sustainability information.

-

Forms

Download the latest Dincel forms.

FAQs

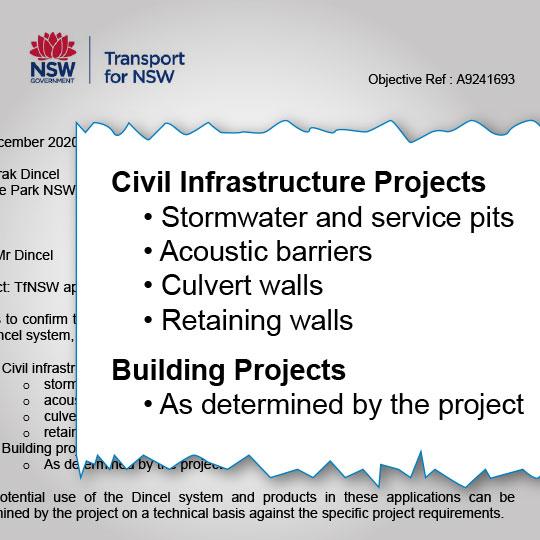

Dincel Structural Walling is a permanent polymer formwork system for concrete walling. It can be used to construct a wide range of concrete walls for civil applications such as:

Retaining walls

Culverts

Tanks

Channels

Pits

Revetment & Sea walls

Erosion protection walls

Parapets

Sound walls

Walls exposed to stray current corrosion

General construction works requiring structural walling

The polymer formwork stays in place after the concrete is poured (formwork is not stripped afterwards), thereby providing the wall with a waterproof and durable skin. This skin protects the concrete and steel reinforcement which increases the lifespan of the walls compared to conventional concrete and masonry structures.

Dincel Civil Solutions is a sister company to Dincel Structural Walling, and uses the Dincel product to provide services to the civil sector. The scope can include anywhere from supply only, all the way to full turnkey packages including:

Engineering design, inspections & certification.

Supply of Dincel components, metal decking, conventional formwork, temporary propping, reinforcement and concrete trade works.

Installation packages including supply of all structural components, plant, equipment and site labour.

Minor excavation, backfill, drainage and associated waterproofing.

Dincel structural walling can be used in virtually all civil segments, including:

Subdivisions

Water and sewer infrastructure (hydraulic)

Roads, rail and marine (subject to Transport authorities’ requirements)

Mining and aggressive environments

Agricultural and food processing

Remediation works

Dincel Civil Solutions are primarily involved with projects in NSW and can engage with projects of all sizes. For larger projects, Dincel Civil Solutions can consider these on a national level.

Dincel hollow formwork panels are ‘snapped’ (clicked) together to build and form the wall. This patented snapping action ensures a safer, faster installation. While connecting panels, steel reinforcement can be added inside the wall as required. Once this is complete concrete is simply poured within the Dincel formwork.

The system comprises of accessories such as corners, caps, guides and joiners in order to streamline the installation process.

Dincel walls are available in 110mm, 155mm, 200mm and 275mm thicknesses. Widths per panel is 333mm for the 110mm, 155mm and 200mm thick profiles, whereas the 275mm thick profile is square and has a width of 275mm. Panel length (height of wall) can be ordered from 1.8m to 7.95m for most profiles.

Wall dimensions do not need to exactly match Dincel standard panel widths, our profiles can simply be cut on-site to suit requirements.

- The formwork can be installed at an incredible rate of 25m2 / 2 people / hour, even by non-skilled labour. This is attributed to the patented ‘snapping’ vertical connection of Dincel panels.

- No crane is required - each 3m long panel only weighs 13kg (for the 200mm profile).

- The ‘stay in place’ polymer formwork provides a permanent waterproof skin to the concrete wall, meaning a Dincel wall does not require further waterproofing other than to wall junctions (please refer to Dincel waterproofing documentation for more information). This:

- Eliminates over excavation on the exterior side to retaining walls – build right up to the boundary and maximise land usage!

- Minimises the amount of the waterproofing products required and the labour to apply them.

- Minimises rectification works – the durable waterproof skin prevents corrosion of steel reinforcement and therefore prevents concrete spalling (concrete cancer).

- The system contains a unique crack inducing technology which:

- Reduces requirements for steel reinforcement within the wall – in some cases it can be eliminated completely. If steel reinforcement is required this can easily be inserted and held into place with the panel’s webs or accessories.

- Enables omission of vertical expansion joints for crack control - leading to reduced finishing and caulking requirements.

- Curved Dincel walls are easily achieved through the use of accessories or simply bending and restraining profiles.

- Generally, very short lead times required for wall installation.

Yes - The 275mm Dincel profile allows for backfilling to be carried out incredibly early, as soon as 24 hours after concreting in most cases (subject to appropriate wall bracing and wall height). This is because the formwork itself provides the capacity to resist backfill loading, and allows for a substantial reduction in construction program. Please contact us for further information on this topic.

Concrete in-filled block walls, conventionally formed in-situ concrete walls, precast/tilt-up walls, conventional brick walls and autoclaved aerated concrete (AAC) walls.

Yes - Dincel is manufactured in Western Sydney, Australia. Please get in touch with us today to see how we can assist in your next civil project.

Yes - The system has been certified by The University of New South Wales (UNSW) and The University of Technology Sydney (UTS). The concrete and steel reinforcement inside Dincel formwork can be designed using AS 3600 or other relevant concrete codes such as Eurocode. The polymer skin and webbing are removed from the wall’s effective concrete thickness for the purposes of structural design. For more information, structural and civil engineers are encouraged to download our structural engineering manual. Alternatively, following testing by UTS in accordance with AS3600:2018 Appendix B, it has been verified that Dincel 275 with its unique ring webbing provides significant benefits against a range of structural actions. If desired, Dincel 275 can be designed as a composite walling system in order to substantially reduce or even eliminate steel reinforcement within Dincel 275 walls.

A myriad of tests have been carried out on Dincel walling to demonstrate the products excellent fire performance. Tests and assessments include:

AS ISO 9705 Room Test performed by Warringtonfire (NATA accredited laboratory)

Group 1 Rating (the highest/best classification)

SMOGRA of 14 (7 times under the NCC limit)

Tested as an entire wall system (not just the PVC skin) to determine actual behaviour

Video of test: https://youtu.be/X-45ymnRAl8

AS 5113 / BS 8414 Façade Test performed by Warringtonfire (NATA accredited laboratory)

Certified by Consulting Fire Engineers to be suitable for external façade walls which are required to be non-combustible.

Tested as an entire wall system (not just the PVC skin) to determine actual behaviour

Video of test: https://youtu.be/Ry4hXJDyN14

AS 1530.4 Fire Resistance Tests

Exceptional Fire Resistance Level (FRL) of up to 240/240/240 – tested at CSIRO

Joint and Penetration specific tests – tested at Warringtonfire. No requirement to remove skin underneath fire rated caulking and fire collars.

Bushfire Attack Level (BAL)

Assessed by CSIRO and confirmed as suitable for use in bushfire conditions of up to Flame Zone (FZ), which is the most severe rating.

Yes - Resistance of the PVC skin against UV radiation is only a consideration when there is no finish applied. However, even when left raw the Dincel polymer does not readily degrade when exposed to UV due to natural inhibitors used within the PVC composition (titanium dioxide/TiO₂). UV radiation causes an excitation of molecular bonds to the exposed face, which only affects the first few microns of the 2500 micron skin. The effects of this are:

Loss of gloss, progression to chalking and discolouration (yellowing). This is only an aesthetic concern, and easily mitigated if required by applying a finish.

An increase in tensile strength, yield strength and moduli, which subsequently increases the possibility of a brittle type fracture. As Dincel walls contain solid concrete on the inside, any impact onto a Dincel wall is absorbed by the concrete infill and not the PVC (unlike a hollow pressure pipe subject to cyclic loading). Therefore, the skin of Dincel walls will be largely resistant to brittle type fractures (if it is even exposed to impact loads in the first place).

Therefore, a raw Dincel wall can serve it’s expected life even if exposed to the sun’s UV radiation.

Yes - A Dincel wall is a concrete wall with an additional PVC skin. This skin is not only formwork but also has the additional benefit of acting as a protective waterproof membrane. By ensuring no water or contaminants enters the wall, the durable PVC skin further enhances the long 120 year life span already capable of being achieved by a conventional reinforced concrete wall.

Please download the document ‘Dincel Compliance Information Sheet – Civil & Transport’ for detailed information on this topic.

Dincel walls can eliminate some of the air void/compaction issues associated with other types of permanent formwork systems:

Dincel polymer forms are non-hygroscopic, meaning it does not absorb moisture from the concrete mix while it is being poured. This ensures no friction between the concrete mix and the formwork itself, allowing for the easy flow of concrete throughout.

Dincel formwork allows for the use of high-slump concrete (180mm+). When coupled with adequate vibration, concrete compaction issues are not possible. Self-compacting concrete can also be considered.

Segregation is eliminated by pointing the concrete pump nozzle towards the Dincel webs, which prevents the free fall of concrete. Alternatively, a tremie can be used if required.

With over 15 years of commercial use the Dincel system has been proven to demonstrate that air voids and segregation do not occur if the correct measures are used. For critical applications, Ground Penetrating Radar (GPR) technology can be utilised to scan the walls and verify that there are no air voids. If required, please contact us for further information regarding the QA processes for concrete compaction.

Please download the document ‘Dincel Compliance Information Sheet – Civil & Transport’ for detailed information on this topic. As Dincel is purely a formwork material, the concrete and steel reinforcement inside can be designed, ordered and placed to comply with the relevant transport concrete specifications and requirements (such as RMS B80, Vic Roads 610 and QLD Transport and Main Roads MRTS70).

No - Standard hand held tools are all that is required for most projects.

The base of the forms is restrained by a Dincel PVC guide (P-G), timber guides or angles, which also establishes the location of the walls. The top of the forms can be braced with either steel (push-pull prop) or timber bracing. Most of the bracing can be eliminated if there is a formworking deck above which the Dincel panels can be simply screwed into.

The unique design of Dincel formwork, as certified by The University of New South Wales, enables steel reinforcement to be eliminated for a wide variety of applications. However, if steel reinforcement is required, please see below installation methods:

Horizontal reinforcement - Central

- Simply feed reinforcement through the horizontal holes provided at 150mm spacing.

Horizontal reinforcement – Two layers

- 155mm & 200mm profiles:

- Use of the Dincel Horizontal Reo-Clip (HRC) accessory which can either clip or slide into the system and provides slots for two layers of bars, or

- The installer can simply fabricate hair-pin (‘U’) bars which are fed into the horizontal holes of the formwork.

- 275mm profile – Simply feed steel reinforcement into the two adjacent horizontal holes which are already provided as part of the profile.

Vertical reinforcement – Central or two layers

- Feed the steel reinforcement through the top of the Dincel formwork at the locations required. The bars can be held in place by:

- Weaving the vertical reinforcement in-between horizontal reinforcement, or

- By use of the Vertical Reo-Clip (VRC) accessory, or

- By tying to a support bar at the top.

No - Refer to the Concrete Mix Specification within the Dincel Construction Manual.

Yes - The system is designed to work best with a concrete pump, and the use of boom pumps is especially recommended. Concrete can also be placed with crane buckets, elevators or other typical placement methods.

Yes - We recommend a 25mm ‘pocket’ vibrator to be used by an experienced operator. Refer to the Dincel Construction Manual for more detail.

No - Provided the ends/corners of the walls are properly braced and the Dincel recommended method of installation is followed, it is almost impossible to have blow outs. Bulging of the forms can occur if a wet concrete mix is dropped into the forms from excessive heights or too fast. It is therefore recommended that the concrete pump discharge is directed to one of the internal webs of the Dincel profile to slow down the free fall of aggregate, avoid segregation and hydrostatic impact pressure. Refer to the Dincel Construction Manual for guidance.

No - This uplift phenomenon occurs with porous formwork surfaces such as fibre cement, masonry blocks or plywood sheets. Since cement slurry does not bond (no water absorption) to the polymer surface of Dincel forms, the formwork uplift which is normally experienced with common formworking systems does not occur with Dincel.

In addition, the round, horizontally aligned web holes of Dincel modules prevent the free fall of coarse aggregate, hence eliminating concrete segregation. The same phenomenon, commonly called elephant-trunk action, pushes the forms down against the potential uplift caused by the wet concrete mix.

For the above reasons no physical connection is required between the bottom tracks/angles and the wall forms. However, in order to prevent the forms from being displaced by wind or accidental impact, it is recommended that the forms should be secured to the bottom tracks/angles.

The system incorporates in-built crack inducers which act as shrinkage movement joints for the Dincel wall. Therefore, joints for standard crack control purposes are not required. However, joints in slabs or footings may need to be carried through and incorporated into the Dincel wall as well.

Typically, the day after pouring the in-situ foundations or slabs. This is confirmed by the project’s consulting structural engineer and is dependent on concrete setting times and the wall design.

The service temperature is the temperature when the material starts to deform. The effective service temperature of a polymer can vary significantly with the rate of loading. Literature explains that small load application rates at high temperatures can have the same effect as large load application rates at lower temperatures.

The maximum service temperature of PVC has generally been understood to be about 65°C. Rigid PVC offers a heat deflection temperature, where softening starts to occur, at 70°C temperature or vicat softening temperature at 75°C.

The polymer used for Dincel is a significantly modified version of common rigid PVC. Fire tests by the CSIRO Australia demonstrated excellent heat release properties which are better than common rigid PVC and even plasterboard. However, irrespective of this it is important to note that a Dincel wall consists predominantly of concrete infill. The strength of the Dincel formwork is only required at the time of concrete pouring to hold the wet concrete pressure. Therefore, the Dincel material, being formwork, only requires serviceability performance at the time of concrete pouring.

Concrete hydration temperatures need to be considered when using high strength concrete in excess of 65 MPa (28 days). The concrete’s hydration temperature is based on many factors including ambient temperature, the concrete temperature and the concrete mix design. Dincel walls have been used to successfully incorporate an 80 MPa concrete mix (28 days). Contact your concrete supplier to confirm the curing temperatures if high strength concrete is considered. As common practice, concrete mix designs are developed in a way to prevent hydration temperatures exceeding 65°C. When 65 MPa concrete is prepared and poured under Australian Standards, it is a rare possibility for the concrete's hydration temperature to exceed 50°C if the thickness of the wall is limited to 275mm as is the case of Dincel formwork. Therefore, there are generally no issues with concrete curing temperatures exceeding the Dincel formwork’s service temperature.

As Dincel walls contain a permanent polymer skin, in their raw state they are left with a clean, white and durable finish. For most civil applications, no further finishing is required. However, if required for aesthetic purposes, Dincel can be finished in a number of ways:

Paint

Render

Cladding (such as stone, timber, tiles, corrugated metal or other cladding systems)

Green Wall

A 100% Acrylic Render must be used - conventional sand and cement render is not suitable. 100% acrylic render is readily available from major suppliers and offered in a wide variety of colours and textures.

For best results check installation steps with the selected render manufacturer. Generally, the following steps are specified:

The surface is cleaned from dirt, grease and concrete slurry.

A coat of surface etching primer is applied to prepare the base for bonding. Otherwise, the surface is mechanically scuffed/roughened.

The etched surface receives a trowelled-on coat of filler component which consists of a polymer compound, flexible enough to absorb movements of the base surface. The purpose of the filler is to fill the joints between profiles and level the surface appearance.

The final finishing coat may consist of either trowel-on, pre-coloured, desired texture finish or two coats of desired paint.

If dark colours are proposed, this must first be checked with the render manufacturer. Some manufacturers offer sun-ray reflectors and suggest a minimum thickness of 10mm to permit the use of dark colours.

No - Dincel panel joints control and minimise the contraction and expansion movements of the wall surface. Any differential movement between the Dincel skin and applied render finish is significantly reduced in comparison to conventional walls. The etching primer prepares the Dincel surface for chemical bonding. The polymer render base coat, being flexible enough, also absorbs any possible movement differential at the matching surfaces. In fact, this combination becomes much more reliable than the conventional cement render applied to masonry, concrete or fibre-cement surfaces.

For lightweight cladding such as timber, corrugated metal and tiles – these can be fixed directly onto the Dincel face using an adhesive or mechanical (screw) fixings. For heavy cladding such as stone, these are typically mechanically anchored into the concrete within Dincel.

No - Currently Dincel is only available in off white. Dincel can be painted for other colour requirements.

Conventional concrete walls crack due to the brittle nature of the material and the process typically starts while the concrete is still plastic. Unlike conventional concrete, Dincel provides an impermeable permanent skin which enables an ideal curing environment and subsequently allows the concrete to achieve additional strength and crack resistance performance. In addition to this, Dincel also provides internal crack inducers at approximately 125mm centres which cracks the concrete at controlled locations in order to act as expansion joints.

The presence of Dincel crack inducers distribute the contraction movements along the length of the wall and hence minimises the surface movement for the paint/render application. The paint/render used with Dincel should possess adequate elasticity to handle the maximum movement at each Dincel panel which is typically 0.8mm [(70-12) x 10-6 x 40°C x 333mm = 0.8mm]. Each Dincel panel joint has been designed to accommodate 1.5mm of movement. Therefore, the elasticity of the paint/render needs to be 0.8mm/1.5mm = 52% at 40°C variation. Special consideration needs to be taken for dark coloured renders where the wall surface temperature may increase significantly.

It is essential to check with the selected render manufacturer:

The elasticity of the system and its suitability to span over panel joints.

If sun-ray reflectors and polystyrene balls are used within the render to reduce temperatures (particularly with dark colours).

Minimum render thickness required for insulation and crack control (typically 10mm).

Joint spacing required for render (typically maximum 5m centres).

Further to this, a high amount of moisture inside the Dincel wall may lead to vapour trying to escape the system and cause cracks at Dincel vertical panel joints. In order to prevent this:

Do not use a concrete mix with a water/cement ratio in excess of 0.5 or allow for water to be added to the concrete mix on site.

Do not block/seal the top of Dincel Wall after concrete pouring. High relative humidity and prolonged rainy periods can increase the water content within a Dincel Wall. It should be remembered that Dincel is a waterproof container particularly after receiving polymer render or paint finish.

Fill and level the damaged part with a two-part resin filler/bog. Once dry, sand the surface.

Apply a coat of etching primer between the joints of the damaged Dincel panel.

Apply one or two coats of paint with matching Dincel colour to the repaired panel.

The Dincel polymer formulation is based upon a proprietary and re-engineered uPVC. Some in the industry have concerns over the environmental sustainability of common PVCs because it contains plasticisers and heavy metal stabilisers during the manufacturing process. However, the Dincel polymer formulation does not use plasticisers or heavy metal stabilisers but rather organic stabilisers. This allows Dincel to be a certified non-toxic product and attain Best Environmental Practice (BEP) certification. Our unique polymer formulation also offers superior fire properties, smoke properties and UV resistance compared to common PVC. The Dincel polymer has been extensively tested and offers the following performance benefits and certifications:

Toxicity of smoke during a fire - 300% below the World Health Organisation (WHO) threshold. It is important to note that although smoke toxicity is not a DTS requirement within the Australian NCC/BCA, it has been tested with Dincel regardless.

Smoke quantity during a fire - 7 times less than the NCC threshold (based upon large scale AS ISO 9705 test)

Volatile organic compound (VOCs) - over 25 times better than the Australian Green Star threshold

Best Environmentally Practice (BEP) certified

Yes:

During Manufacturing

All manufacturing waste, including extrusion rejects, off-cuts and cored web holes are almost 100% recycled by Dincel’s superior manufacturing technology.

During Construction

Dincel provides custom profile lengths between 1800mm and 7950mm which significantly minimises the need for cutting and creating construction site wastage. Any Dincel product that cannot be used on site can be sent to third parties for recycling (the same standard practice as the PVC pipe industry).

End of Life

As Dincel can be designed to have reinforcement in the vertical direction only (or no reinforcement at all), it allows the recycling of vertical steel bars, concrete infill and Dincel’s polymer formwork at the end of building life with greater ease. The absence of steel bars in the secondary direction enables easy separation of steel bars from the concrete infill.

Yes - ‘The Natural Step’ consultants carried out life cycle assessment of Dincel walls and concluded the system “offers significant and compelling sustainability advantages for the construction industry” (please download this document on our website for further information). Dincel walls offer significant sustainability benefits over conventional concrete walls such as the ability to omit crack control steel reinforcement, reduce cement content from concrete mixes, and provide a longer life-span due to the polymer protective skin.

Dincel has attained Best Environmental Practice (BEP) certification as the product is plasticiser free, heavy metal stabiliser free and has a VOC rating over 25 times better than the Australian Green Star rating threshold.