Fire & Non-Combustibility

Compliance tested by CSIRO and Fire Engineering and satisfied:

- Non Combustible

- Fire rated 90 – 240 minutes

Download Fire Assessment currently under revision for addition of ISO 9750 and AS5113/BS8414 test results.

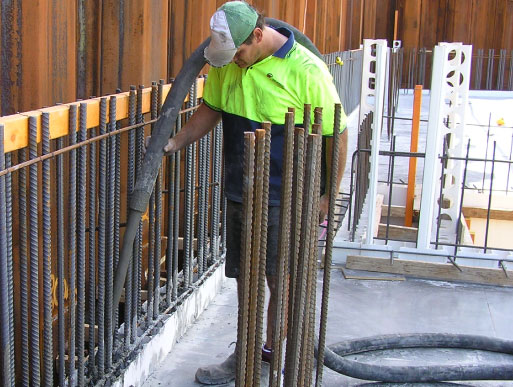

In the civil Infrastructure market, most structural walling is still constructed using either cast in situ or precast concreting. While these traditional methods are reliable, they are also time-consuming. In situ concreting, for example, requires a lot of manpower and infrastructure.

Dincel Structural Walling, an innovative polymer formwork system made by Sydney-based manufacturer Dincel Construction System, changes all this. A faster and easier way to install waterproof and reinforced concrete walls, it cuts back on labour hours, requires less reinforcing than traditional methods and eliminates the need for things like cranage and timber formwork.

The key difference between the Dincel system and traditional techniques is that the concrete core of the structural wall is encapsulated within a protective polymer skin (long PVC panels that are in place prior to the concrete pour).

The brainchild of the company’s founder Burak Dincel, Dincel Structural Walling was introduced in 2006. Originally available in 110mm, 155mm, and 200mm profiles, it initially found favour among small to mid-sized residential builders. The recent release of a new 275mm profile has opened up new opportunities for specifiers in the civil infrastructure market to use the product.

Dincel Structural Walling has been assessed and issued with a CodeMark Certificate of Conformity for Type A, B & C construction covering all internal/external wall applications; openings and penetrations (i.e. Fire collar use directly onto Dincel Wall and Dincel Wall abutting to a non-Dincel wall). It has been Fire rated (90-240 minutes) and certified as suitable for bushfire prone areas (BAL Low to BAL FZ).

In addition, Dincel Structural Walling has been tested under 6 m of water head pressure and certified as waterproof by CSIRO Australia.

Benefits for Construction:

Dincel Structural Walling is the smarter, faster & more economical alternative to conventional masonry blockwork, particularly in the multi-residential space. Delivering quicker project turnarounds, reduced costs, and cleaner and safer construction sites, Dincel walling erases the need for specialised trades.

Dincel’s unique polymer formwork is impervious which means it does not suck water from the wet concrete – unlike conventional formwork – which being porous can lead to corrosion/concrete degradation issues such as honeycombing and air voids which can be expensive to rectify.

Conventional concrete is porous which leads to corrosion and concrete degradation issues. Concrete cracking is unavoidable, inadequate concrete cover, honeycombing and air voids can lead to concrete cancer.

Dincel’s polymer is impervious which does not suck water from wet concrete. Therefore no friction occurs between the formwork and concrete infill, preventing honeycombing and air voids.

Designed with an impervious vapour barrier for both faces along with built-in crack control joints that eliminate the need for crack control steel.

Dincel Wall encapsulation achieves greater concrete strength by minimising moisture evaporation throughout the curing process.